NDTScan provides advanced non-destructive testing (NDT) solutions tailored for maritime and underwater assets. Our services ensure accurate, compliant, and efficient diagnostics across all sectors, from aerospace to infrastructure. With cutting-edge equipment and over a decade of experience, we deliver certified inspections that minimise downtime and maximise safety. Trust NDTScan for reliable, data-driven reporting that enhances your decision-making and operational excellence.

NDTScan safeguards lives and extends the operational lifespan of critical maritime and underwater assets across the UK and Europe. From harbour structures to offshore platforms, we deploy advanced non-destructive testing (NDT) methods to identify hidden deterioration, corrosion, and structural faults without intrusive or destructive intervention.

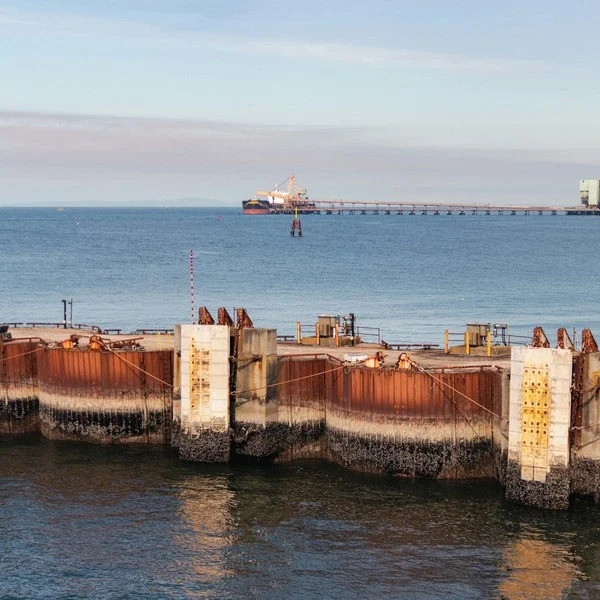

Our inspections are vital. We detect failures that threaten safety and commercial operation, from submerged pile corrosion to internal voids in quay walls and jetty foundations. Using underwater ultrasonic scanning, sonar imaging, magnetic particle testing, and drone-based visual surveys, we deliver forensic insights into both above and below waterline structures.

We don’t just scan — we prevent catastrophic failures, minimise repair costs, and help asset owners and operators make decisive, evidence-backed interventions. We ensure that maritime structures meet safety, insurance, and operational compliance standards, protecting infrastructure and human life alike.

Hidden Threats Beneath the Surface

Marine environments accelerate degradation in ways that are often invisible until failure occurs. Tidal action, saltwater exposure, biological growth, and galvanic corrosion combine to compromise structural integrity at an alarming rate. The cost of unaddressed faults can be catastrophic, both financially and in terms of human safety.

NDTScan leads the field in detecting hidden maritime risks before disaster strikes. Our underwater ultrasonic thickness gauges, remote visual inspection drones, and sonar systems provide verifiable evidence of asset condition, wall thickness, section loss, and crack propagation — even in the harshest environments. We empower port authorities, offshore operators, and engineering firms to act decisively and with confidence.

How We Survey Maritime and Underwater Assets

Every maritime asset is unique, but the degradation patterns are predictable. Our structured inspection approach applies to piers, jetties, offshore platforms, sea defences, underwater pipelines, and submerged civil structures. All our scanning and testing equipment is fully portable, battery-powered, and rated for marine and underwater deployment.

We operate with minimal disruption to port operations, vessel movements, and offshore production schedules. Surveys can be scheduled around tidal cycles, operational downtimes, or vessel berthing plans. Urgent findings are reported immediately, with full reporting and CAD overlays typically delivered within 24 hours.

Our Maritime and Underwater Assets survey techniques include:

- Underwater Ultrasonic Testing (UT): Accurately measures steel thickness and section loss below the waterline.

- Sonar Imaging: Provides detailed visualisation of submerged structures, scour patterns, and seabed interfaces.

- Magnetic Particle Inspection (MPI): Detects surface and near-surface cracks in ferrous materials above and below the waterline.

- Drone and ROV Inspection: High-definition imagery of inaccessible marine structures, above and below the surface.

- Cathodic Protection Surveys: Evaluates the effectiveness of corrosion prevention systems on submerged assets.

- Thermographic Analysis: Identifies moisture ingress, voids, and internal weaknesses in sea-facing concrete structures.

Why Maritime Clients Choose NDTScan

We operate across all UK ports, offshore wind farms, naval bases, and maritime infrastructure projects. From routine maintenance checks to emergency response after storm damage, our experienced teams deliver rapid mobilisation and uncompromising technical expertise.

Our reporting is engineered to meet the requirements of asset managers, insurers, engineers, and regulatory authorities, ensuring swift remedial action and optimised lifecycle management for critical maritime structures.

Non-Destructive Testing for Maritime and Underwater Assets

NDTScan is a trusted partner in safeguarding the long-term performance, safety, and compliance of maritime and underwater assets. With expertise spanning ports, offshore energy platforms, breakwaters, and submerged infrastructure, we provide industry-leading non-destructive testing (NDT) solutions that offer critical insight without interrupting operations or damaging vulnerable structures.

Our goal is simple: to detect degradation before it becomes failure. The harsh and unpredictable nature of the marine environment demands proactive inspection strategies. Our Maritime and Underwater Assets teams operate in all conditions—above and below the waterline—to deliver actionable intelligence that supports operational safety, insurance compliance, and asset preservation.

We don’t just assess — we help port operators, marine engineers, and offshore maintenance teams act with confidence in the face of hidden risk.

Managing Risk in a Corrosive and High-Stress Environment

Maritime and underwater assets are exposed to some of the most aggressive conditions known to civil engineering. Saltwater, biofouling, constant wave loading, tidal cycles, and galvanic reactions all contribute to accelerated material degradation and unpredictable structural wear.

Unseen threats include:

-

Pitting corrosion and wall thinning in steel piles and caissons

-

Spalling and internal voids in submerged concrete

-

Crack propagation in welded joints under cyclic stress

-

Scour and sediment erosion at seabed foundations

-

Shielded corrosion beneath coatings or marine growth

-

Electrical system failure due to ineffective cathodic protection

NDTScan’s inspection programmes are designed to identify these threats early and precisely—before they escalate into operational shutdowns or structural failure.

Where We Operate – Maritime and Underwater Assets

Our maritime inspection services apply across:

-

Commercial ports and harbours

-

Naval dockyards and military infrastructure

-

Offshore wind platforms and subsea energy structures

-

Jetty decks, piles, and fender systems

-

Underwater pipelines and risers

-

Flood barriers and tidal control gates

-

Bridges, tunnels, and causeways with marine exposure

-

Dry docks, caissons, and lock gates

We work around scheduled operations, tidal cycles, and vessel traffic, offering both planned inspection windows and emergency response capability following storms, collisions, or structural alarms.

Inspection Techniques for Maritime and Underwater Assets

We deploy a suite of portable, field-proven tools designed specifically for submerged and splash zone environments.

Underwater Ultrasonic Thickness Testing (UTT)

Our diver-deployed and ROV-mounted UT systems measure:

-

Steel wall thickness

-

Section loss and corrosion damage

-

Remaining life of protective coatings

-

Integrity of risers, piles, and jacket components

All Maritime and Underwater Assets readings are traceable, repeatable, and fully logged to support long-term condition monitoring programmes.

Sonar Imaging and Profiling

Using sector and multibeam sonar, we visualise:

-

Underwater structure outlines and surface condition

-

Scour patterns and seabed erosion

-

Submerged defect features or voids

-

Pipeline alignment and trenching conditions

Sonar is especially effective in low-visibility waters and deep structures where diver access is restricted.

Magnetic Particle and Dye Penetrant Inspection

These techniques are used for:

-

Surface-breaking cracks in mooring fittings, bollards, braces, and structural steel

-

Weld integrity checks on marine-access steelwork

-

Above-waterline inspections on platforms, gangways, and exposed assets

MPI and DPT are fast and reliable methods for structural crack detection on ferrous materials.

Drone and ROV-Based Surveying

We operate aerial and submersible platforms equipped with:

-

4K and thermal imaging cameras

-

Laser scaling and sonar add-ons

-

Live data streaming for remote viewing

-

Environmental payloads for sediment and current monitoring

Maritime and Underwater Assets ROVs are ideal for submerged asset inspection in confined or high-current environments, such as sea walls, submerged tanks, and flood defence intakes.

Cathodic Protection (CP) Surveys

Our CP surveys assess the effectiveness of:

-

Anode arrays on offshore structures

-

Buried cathodic systems in pipelines

-

Galvanic or impressed current protection for marine vessels and structures

We help clients ensure compliance with ISO 15589 and DNV standards for CP performance and inspection intervals.

Thermographic Maritime and Underwater Assets Imaging

Thermal surveys are used for:

-

Detecting moisture ingress in concrete sea defences

-

Identifying thermal anomalies in dockside buildings or chilled storage areas

-

Monitoring power systems within marine installations

Thermography supports visual assessments and identifies non-obvious asset vulnerabilities.

Reporting and Decision Support for Maritime Infrastructure

All NDTScan Maritime and Underwater Assets inspection results are compiled into structured, audit-ready reporting, including:

-

CAD-integrated defect maps

-

Ultrasonic thickness logs and corrosion trending

-

Sonar imaging overlays and video captures

-

Thermal or visual imagery with annotations

-

Remedial recommendations prioritised by risk and severity

-

Compliance references for ISO, DNV, and marine insurer standards

Our Maritime and Underwater Assets reporting is tailored to meet the needs of port engineers, offshore maintenance planners, asset owners, and marine insurers alike—ensuring a clear path from data to action.

Why Marine Operators Choose NDTScan

We are trusted by:

-

Port and harbour authorities

-

Maritime infrastructure managers

-

Offshore energy operators

-

Marine contractors and diving teams

-

Insurance adjusters and marine surveyors

Our ability to operate in high-risk environments, deliver fast-response inspections, and provide defensible reporting underpins critical decision-making onshore and offshore.

We are known for our:

-

24/7 rapid deployment capability

-

Field-proven inspection technologies

-

Minimal disruption to marine operations

-

Confidential, standards-aligned reporting

-

Experience across both public and commercial marine sectors

From structural assurance of tidal barriers to lifespan extension of ageing quay walls, we help Maritime and Underwater Assets clients plan, protect, and invest with total confidence.